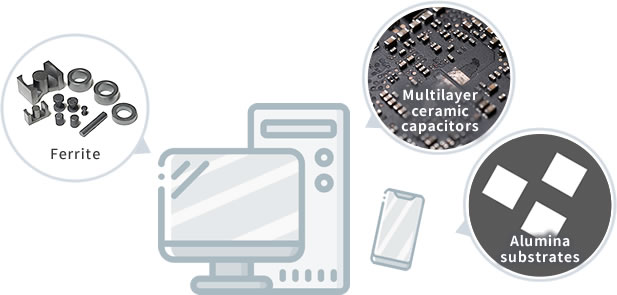

What are refractory products for ELECTRONIC PARTS?

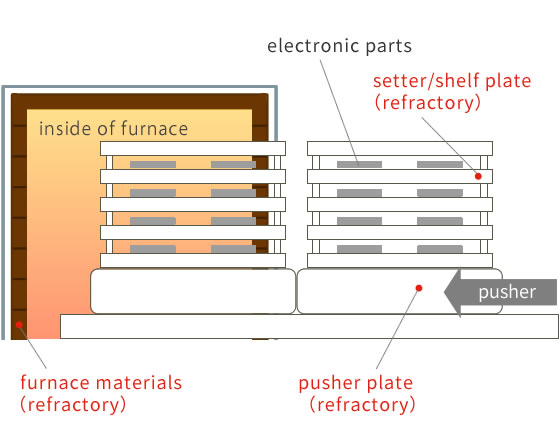

Many kinds of electronic parts (semiconductors), such as alumina substrate, MLCC, and ferrite, are used in smartphones, personal computers, cars, and televisions, which are commonplace in our lives. These electronic parts are treated at high temperatures in their manufacturing processes, and our refractories are used for such treatment.

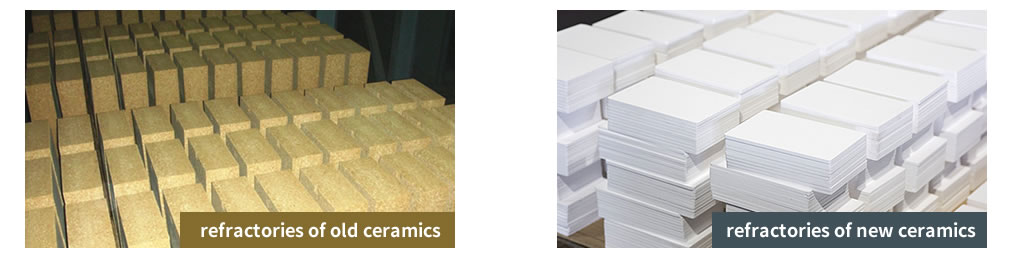

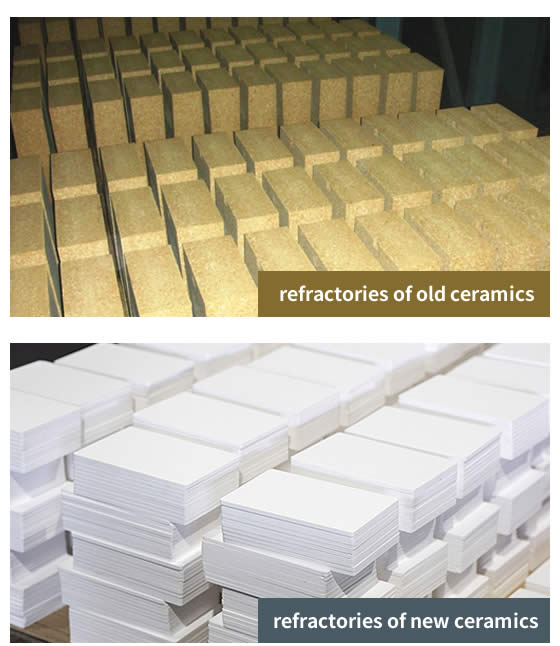

Classification of ceramics

While many refractories for iron, steel, and cement manufacturers are manufactured using natural minerals, the refractories for electronic parts manufacturers generally use new ceramics made from natural and artificial raw materials refined at high purity.

Why needs refractories of new ceramics?

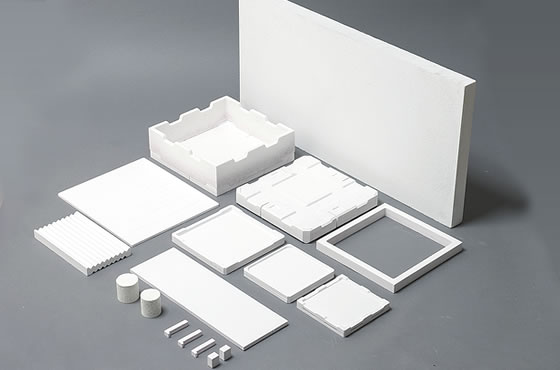

This is because the refractories for electronic parts are required to have smooth surface and few impurities.

High-precision new ceramics made of highly pure raw materials are used because electronic parts directly contact refractories and must avoid being damaged or bent during high temperature treatment.

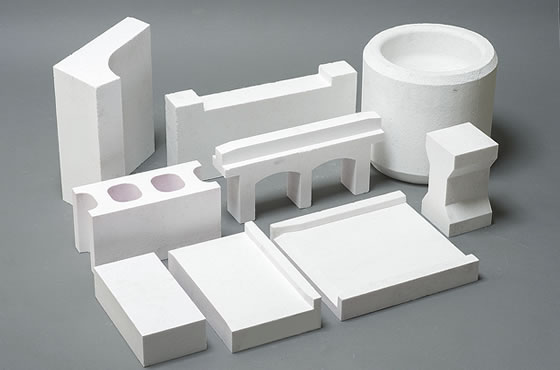

Kiln furniture to fire new ceramics

The products are manufactured through high-pressure molding and ultrahigh-temperature burning processes, using highly pure electro-fused alumina and electro-fused mulite as raw materials. Therefore, they are stable against thermal, mechanical, and chemical actions under high temperatures and offer excellent thermal shock and creep resistance.

Furnace materials

The products are produced by the refractory manufacturing technology that we have cultivated over the years and our strictly controlled manufacturing processes. As they are products fired at high temperatures, they work stably in different types of burning furnaces used at high temperatures and remain chemically stable even under a reducing atmosphere.

The electronic parts industry is expected to develop further with the development of artificial intelligence (AI). By boundlessly pursuing the quality required by customers, we aim to be a company that promotes the development of new products based on the symbiosis with customers, and we will continue to offer high-quality products.