This may be the first time for you to hear the term refractories. This is no wonder, since we have little opportunity to experience refractories in our everyday lives. As a matter of fact, the necessities of life, such as personal computers, smartphones, and cars, cannot be created without refractories. They are necessary to create materials for the things around us. Yotai’s refractories support our lives behind the scenes.

What are refractory products?

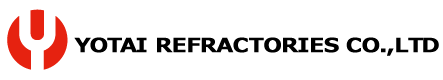

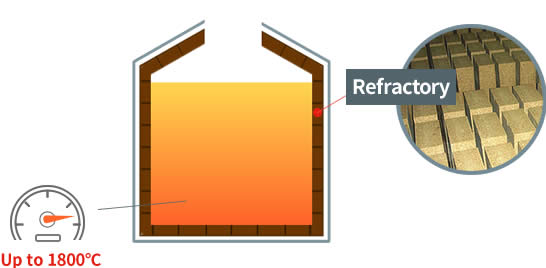

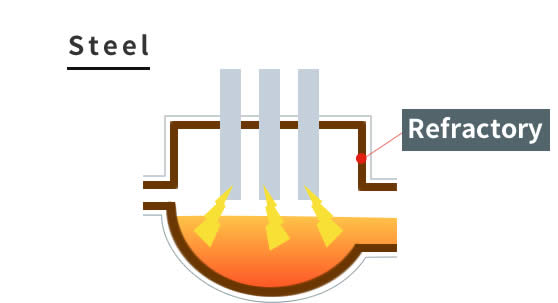

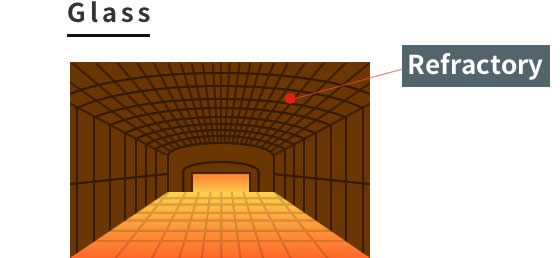

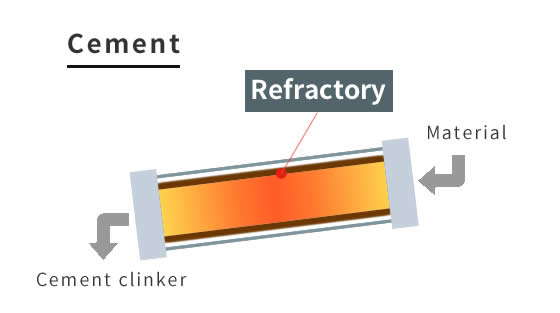

In the process of manufacturing iron, cement, and copper, they need to be melted and baked at high temperatures. However, many pieces of equipment cannot stand such high temperatures because they are made of iron and stainless steel.

Therefore, refractories that have higher heat resistance than the materials to be melted and baked are essential.

Who needs our products?

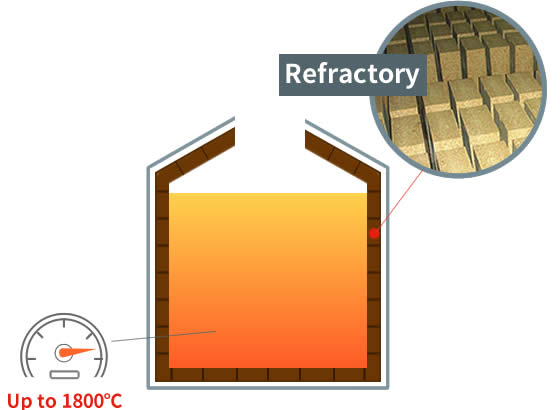

Refractories are needed in a wide variety of industries and are always used in plants with high-temperature treatment processes. The required performance of a refractory depends on the type of material to be heat-treated and the place where it is used.

We offer products with different quality levels as needed in the respective industries and provide optimum products to customers by deepening technological exchanges with customers.

Industries we work for

Steel

Cement

Nonferrous

Glass

Environment

Chemistry

Lime

Carbon black

Electronic parts

How long refractory products life?

Refractories are always exposed to high temperatures and deteriorate over time. The lifetime of refractories varies depending on the application and range from only one day to 10–20 years. The service life is greatly affected by the type of industry and place where refractories are used.

Classificationof refractory

Refractory bricks

Among refractories with a wide variety of shapes, such as block and plate. Refractory bricks are used in the various industries including the electronic parts industry, which is a growing field.

Refractory bricks No. 1 domestic market share

A leading company in the industry

We boast an overwhelming share in the field of refractory bricks

by sharing wisdom among all employees in a cooperative way and always meeting customer needs flexibly and rapidly amid the great changes in the surrounding environment over time.

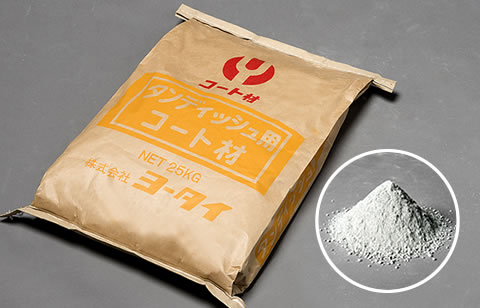

Monolithic refractories

Powder-type and rammed earth-type refractories

Powder-type products are poured after being mixed with water on-site or sprayed for use.

Rammed clay-type products are pressed or patted for use.

Main customers of YOTAI

| Industry | |||||

|---|---|---|---|---|---|

| Steel | NIPPON STEEL CORPORATION | JFE Steel Corporation | TOKYO STEEL MANUFACTURING CO.,LTD. | Sanyo Special Steel Co., Ltd. | Daido Steel Co., Ltd. |

| Non-Ferrous | Sumitomo Metal Mining Co., Ltd. | JX Advanced Metals Corporation | DOWA HOLDINGS CO., LTD. | MITSUI MINING & SMELTING CO.,LTD. | Hibi Smelting Co., Ltd. |

| Cement | Sumitomo Osaka Cemetnt Co., Ltd. | TAIHEIYO CEMENT CORPORATION | Mitsubishi UBE Cement Corporation | Denka Company Limited | Tokuyama Corporation |

| Glass | AGC Inc. | Nippon Electric Glass Co., Ltd. | Nippon Sheet Glass Co., Ltd. | Tosoh SGM Corporation | Nitto Boseki Co., Ltd. |

| Environmental equipment | Ebara Environmental Plant Co., Ltd. | Kanadevia Corporation | JFE Engineering Corporation | JFE Environment Technology Company, Limited | TSUKISHIMA KANKYO ENGINEERING Ltd. |

| Electronic Parts | KYOCERA Corporation | MARUWA CO.,LTD. | TDK Corporation | Electro Ceramics(Thailand) CO., LTD. | NICHIA CORPORATION |

| Chemical & Pottery | TOKAI CARBON CO., LTD. | NGK INSULATORS, LTD. | SEC CARBON, LIMITED | Resonac Corporation | ENEOS Corporation |